TroublePad: an adaptive high speed camera system for industrial monitoring

High speed camera for production lines

TroublePad is a high speed camera solution that enables the identification of production line improvement points. It can be used alongside your existing industrial monitoring system. Easy to use and intuitive, our ultra-portable high speed camera system was created with industrial maintenance in mind. It will enable you to diagnose and understand the anomalies and defects in your production line and high speed machinery.

The TroublePad is aimed at industries that run production lines, such as the food industry, cosmetics, packaging or pharmaceuticals, etc.

About High speed camera TroublePad for production lines

Easy to install, practical to use

Our development departments and our customers' personnel worked together to create the TroublePad, which is designed to facilitate maintenance and optimisation of industrial processes in any field (food processing, pharmaceuticals, bottling, manufacturing, packaging, cosmetics, automotive, paper, electronics, etc.).

What is TroublePad made up of?

The ultra-compact system consists of a high speed camera unit, a tablet with pre-installed software, a mounting arm and a convenient carrying case (9kgs).

It only takes seconds to install, even in the most confined spaces. It is fully mobile thanks to its integrated, directional LED lighting, with no unnecessary wires or power supply (approx. 2 hours stand-alone operation).

A power connection is required when TROUBLEPAD is used to capture a random event which, by definition, could occur at any time over a period of hours or even days...

An intuitive, intelligent and independent high speed camera

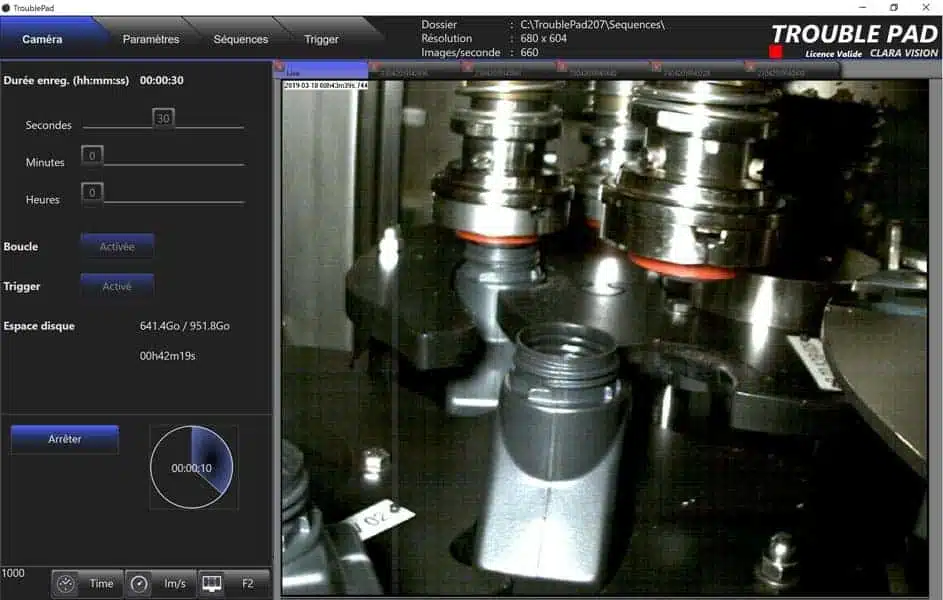

The TroublePad comes complete with preinstalled software on a touchscreen tablet.

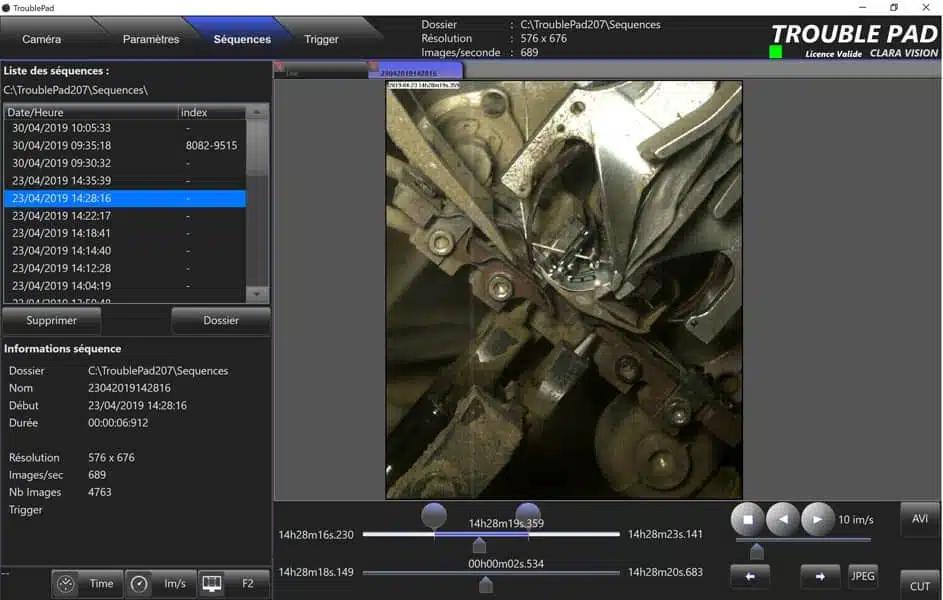

Its intuitive user interface enables you to control recordings, visualise live images, see footage history and enjoy instant replay at slow speed so you can understand production line errors, which are usually impossible to detect with the naked eye, in real time.

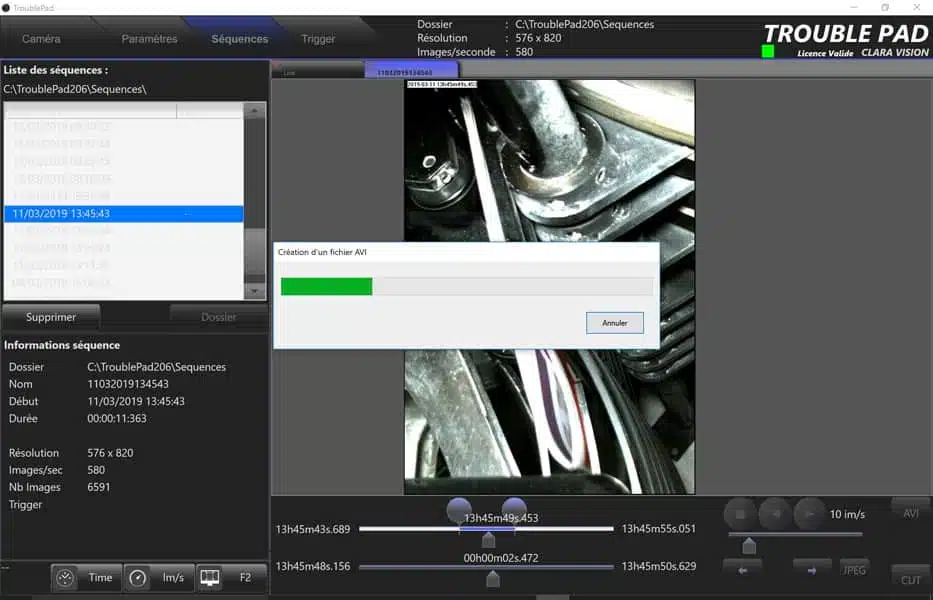

The system also enables videos to be exported in AVI format.

Thanks to this intuitive camera you will be recording your first images just a few minutes after installation.

The TroublePad is an adaptive, intelligent, high precision device for optimal industrial vision.

It can be used as a complement to an existing industrial vision installation or as the sole monitoring device.

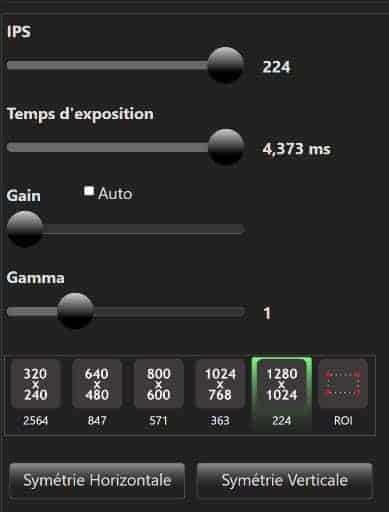

With the camera and TroublePad system, you can set recording speeds from 225 to 2,500 frames per second, and make operator-controlled and configured loop recordings of several hours' duration.

The (optional) Trigger Box provides control over the system and gives it autonomy.

The Box enables you to:

- start recording

- stop recording

- add markers to key frames,

- store a few seconds before and after a signal from your sensors...

You therefore only keep the most essential recorded images. The Box has the added advantage of quickly identifying areas for improvement in the production line, preventing problems more effectively, and helping you to find solutions for each one.

With the Box, the TroublePad becomes a completely standalone device: the images that are filmed are automatically recorded, without the need for human intervention. It provides the system with an extra dimension.

The camera's technical features

From a technical point of view, the TroublePad system is extremely efficient and meets several types of requirements.

The TroublePad camera can operate at a frame rate of 225 to 2,500 fps.

The recommended camera speed is 570 fps with a resolution of 800x600 pixels.

It is also possible to use a more standard speed, 225 frames per second, with a higher image resolution (1280x1024).

Other speeds are also possible, such as 835, 1500 or 2500 frames per second, with lower image resolutions.

The camera is also equipped with a LED light unit, which can operate on batteries (5 AAA batteries) and power packs. It produces 600 lumens.

The optics include a housing with a macro zoom lens to ensure maximum precision when recording. The mounting arm supplied is a magic arm with an adjustable clamp. It adjusts to the camera and its lighting system.

The tablet's technical features

Our system also includes a 12-inch tablet with a powerful Intel Core processor, 8 gb RAM and a 256 gb SSD hard drive, which comes with a protective case and shoulder strap.

For those who require extra storage space, it is possible to select a tablet with a 512GB or 1TB hard drive. The larger capacity tablets can handle longer recording loops.

The very powerful software can record at several speeds, several resolutions, under operator control or independently (with the Box).

TroublePad accessories

Several system accessories are available such as:

- magnetic base

- trigger box

- wireless TroublePad trigger

- high-power lighting (12000 lumens)

- hybrid cable (10, 20 or 50 metres)

- battery kit for the lighting

- wide-angle lens for the camera

- 512 GB tablet

- 1TB tablet

- camera tripod

- clamps for quick attachment

- detachable trolley for the carrying case

- a suction cup for attaching the system

- TroublePad's high speed video software is easier to use than any other.

- It is the operational heart of the high speed video workstation.

The operator will be ready to record sequences using the high speed camera in a matter of minutes.

TroublePad high speed camera enables image acquisition speeds ranging from 225 to 2500 frames/second.

Loop recording (loop duration is defined by the operator) enables continuous recording for several hours, and recording can be stopped either manually by the operator or automatically by an external "machine" trigger.

Ease of use and efficiency are our bywords!

As an option, the TroublePad high speed camera can be set up as a slave to your production line and/or robots!

TroublePad's trigger box can be used to start and stop recording, to mark key frames, to retain a few seconds before and after your sensors' signal....

- The aim is simple....to only keep what you need!

Using the trigger box will help you to easily spot and solve random and infrequent events on your production line.

The TroublePad camera acts as a real "watchdog" for you production line.

Standard speed 225 frames/sec at 1280*1024 resolution

Other possible speeds 835 frames/sec at 640*480 resolution

1500 frames/sec at 500*300 resolution

2500 frames/sec at 320*240 resolution

Lighting Adjustable 96 LED, operating on batteries (5*AAA)

Power 600 lux. Mass 195 gr.

Optics C mount 8-48 mm macro zoom lens

With Close up lens: 1D, 2D, 4D, 10D

Mount 'Magic' arm with variable friction

for high speed camera and lighting

Tablet 12 inch tactile screen

Intel Core Processor – 8 Gb RAM – 256 Gb SSD disk

With protective case and shoulder strap

Carrying case overall dimensions 575x470x205 mm

Weight 9 kg

Key software features Loop recording

Long recording time

Pre/post triggering

Event marking

Backward or forward playback

Adjustable playback speeds

Sequence selection/extraction...

- Video overview of TroublePad high speed camera

- Our high-speed camera filming the application of lids on yoghurt pots

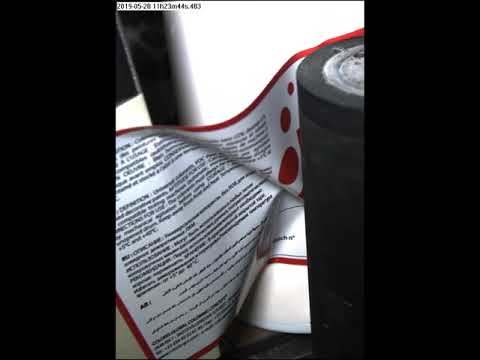

- Viewing a label press setup with a Trouble PAD high-speed camera

- Analysis of a champagne bottle capping line using a high-speed camera

Application note Sheet cutting line

Industry | Application | Product |

|---|---|---|

Papermaking | Sheet cutting line | TroublePad |

First, a special machine lays out and cuts large sheets that are stacked in batches of 500. The reams of paper are then wrapped. These layout and finishing operations require the machinery to be perfectly adjusted and all components to be in good condition. The Trouble Pad camera displays the stacking and cutting sequences. Maintenance technicians can access slow-motion images of the machinery in operation. They can accurately identify the fault and act quickly to adjust settings or replace components as required. The slow-motion feature is a real boon when searching for phenomena that are impossible to see with the naked eye ! Conclusion : Thanks to the Trouble Pad system, the Clairefontaine papermaking factories and the Hamelin group have access to information that would be impossible to detect with the naked eye. Slow-motion images simplify machinery tuning and maintenance operations. The Clairefontaine paper mills and the Hamelin group have been using Trouble Pad at their production sites since 2018. | ||

Application note Vaccine/drug manufacturing line

Industry | Application | Product |

|---|---|---|

Pharmaceutical industry | Vaccine/drug manufacturing line | TroublePad |

Conclusion : | ||

Application note Packaging line

Industry | Application | Product |

|---|---|---|

Special machinery | Packaging line | TroublePad |

Many adjustments are required in order to ensure the packaging machines function correctly during assembly/manufacture. Operators are faced with high-speed sequences that cannot be broken down by the naked eye. The Trouble Pad camera makes it possible to break those sequences down. Technicians can then identify precisely the improvements that need to be made thanks to the slow-motion images. The machines are quickly adjusted, and promptly shipped and installed on site. In addition, field technicians can take the camera kit on site to save time on certain delicate adjustments. The slow-motion footage saves valuable time on their callouts. Conclusion : Thanks to the Trouble Pad high-speed camera, setup and adjustment times are improved. | ||

Application note Component manufacturing

Industry | Application | Product |

|---|---|---|

Electricity | Component manufacturing | TroublePad |

To guarantee production quality, technicians must ensure that the line is not disrupted by sudden movements. These movements sometimes occur at random. In addition, there are many different items, requiring fine machinery adjustments for each new production run.. The high-speed Trouble Pad camera detects the disruptive movements, which are invisible to the naked eye. Maintenance technicians can view slow-motion images of the mechanical parts as they move. They can precisely identify the defect and act on the appropriate parts of the machine. The slow-motion images are easily accessible, as the installation of the Trouble Pad high-speed camera only takes a few minutes ! Conclusion : Thanks to the Trouble Pad high-speed camera, motion detection enables technicians to quickly correct defects, with minimal shutdown times. | ||

Application note Bottling

Industry | Application | Product |

|---|---|---|

Agri-food | Bottling | TroublePad |

The machines must be perfectly tuned to maintain production rates (50-70,000 bottles /hour). There are many parameters involved: new capsule design, empty bottle weight, size variations. Random desynchronisation events can occur in the machine cycle and shut down production.

The high-speed Trouble Pad camera detects these slippages, which are invisible to the naked eye. Maintenance technicians can view slow-motion images of the mechanical parts as they move. They can identify the specific defect thanks to the high-speed Trouble Pad camera. In addition, there may also be a security issue for personnel given the speed of these machines. The machine can then be recalibrated, quickly and safely. The High-speed Trouble Pad camera is a precious asset and the slow-motion images are accessible in just a few minutes ! Conclusion : Trouble Pad reduces production shutdown times and improves line productivity. | ||

Application note Bottling

Industry | Application | Product |

|---|---|---|

Agri-food | Bottling | TroublePad |

The machines must be perfectly tuned to maintain production rates. There are many parameters: the type and thickness of the capsule, surface condition and size variations. Random desynchronisation can occur in the machine cycle and shut down production. The high-speed Trouble Pad camera detects these slippages, which are invisible to the naked eye. Maintenance technicians can access slow motion images of the mechanical parts as they move. They can identify the specific defect thanks to the slow motion. The machine can then be recalibrated quickly. Conclusion : Production downtime has been reduced thanks to Trouble Pad and the slow-amotion images, | ||

Application note Paper production line

Industry | Application | Product |

|---|---|---|

Hygiene | Paper production line | TroublePad |

During the production process a machine is used to cut precise lengths of sheets of absorbent paper. Technicians must ensure that rotating cylinders are perfectly adjusted so as not to break the flow of these cut sheets. With the tablet that is connected to the Trouble Pad high-speed camera, the operator can see the sheet as it is passes over a spinning roller. The ultra-fast rotation of successive rollers can cause the sheet to fold over on itself. This crease usually causes quality defects on the finished product. Similarly, when making absorbent or tissue papers, the machines operate at very high speed and require incredibly precise settings. The machinery’s movements are invisible to the naked eye. Maintenance technicians can see the mechanical parts moving in slow-motion using the Trouble Pad’s high-speed video footage. They can install the TroublePad camera in parts of the machinery that humans cannot access, to identify the defect that they would otherwise be unable to see. Setting up the camera only takes a few minutes! The source of the disruptions can then be identified, and quality improved. Conclusion : Motion detection enables technicians to view the position of the roll of paper. As a result, defect (creasing) detection occurs earlier in the process and avoids quality defects on the finished product. ONTEX has been using Trouble Pad since 2018 at its production sites in France and Spain. Essity Gien, Kunheim and Mannheim use it … as does Kimberly-Clark in Rouen. | ||

Christopher MALLERON-FONTAINE - Maintenance Manager - Isigny Ste Mère - France

We used to use Go-Pro type cameras as part of our maintenance tasks on packaging machines.

After realising the technical limitations of this type of camera, we turned to a professional model, the TroublePad camera by Claravision.

This equipment is very effective in its role, and we have been able to achieve unprecedented results.

On certain machines, which move at very high speed, we have been able to detect defects that the naked eye could not pick up. Using the software to slow down the footage, we were able to remove these defects very quickly.

Plus, thanks to its trigger command and loop mode, we were able to set the TroublePad camera on long surveillance (3 days, 24hr/24) and automatically only retain the footage with the fault we were looking for.

The software is easy to use and intuitive: our technicians can use it after only an hour’s training session.Claravision’s technical department is very responsive if we need advice or help with using it.

The Troublepad camera has become a tool in its own right in our maintenance department, helping with diagnostics, and we encourage our technicians to use it as much as possible.

Jay - HP Inc. - USA

The TroublePad has been very good troubleshooting upgrade for HP inkjet cartridge manufacturing.

Our older cameras were large and so were the lights – it could be difficult to get good angles on moving parts that were inside of machines or behind guards.

With the TroublePad, we can easily mount the camera and lights inside the tool. The software has been very good – the ability to keep the camera running on a loop using various triggering options gives us a lot of flexibility.

Maybe the best thing of all is how self-contained it is. With older high-speed camera setups, engineers would have software installed on their personal laptops and you’d have to deal with drivers, Windows configurations, etc.

With the TroublePad, anyone can just grab the camera case and everything they need is inside it.