This interactive grain size measurement tool is an ideal addition to your Perfect Image software package.

Thanks to the Grani module, metallurgical microscopy laboratories can measure grain size in metals and alloys. An integral part of the Perfect Image analysis software suite, the Grani module is an indispensable tool for many metallography laboratories.

Today we’re going to explain why!

About Grain size measurement in metallography : Grani

Performing different measurement types using the Grani module

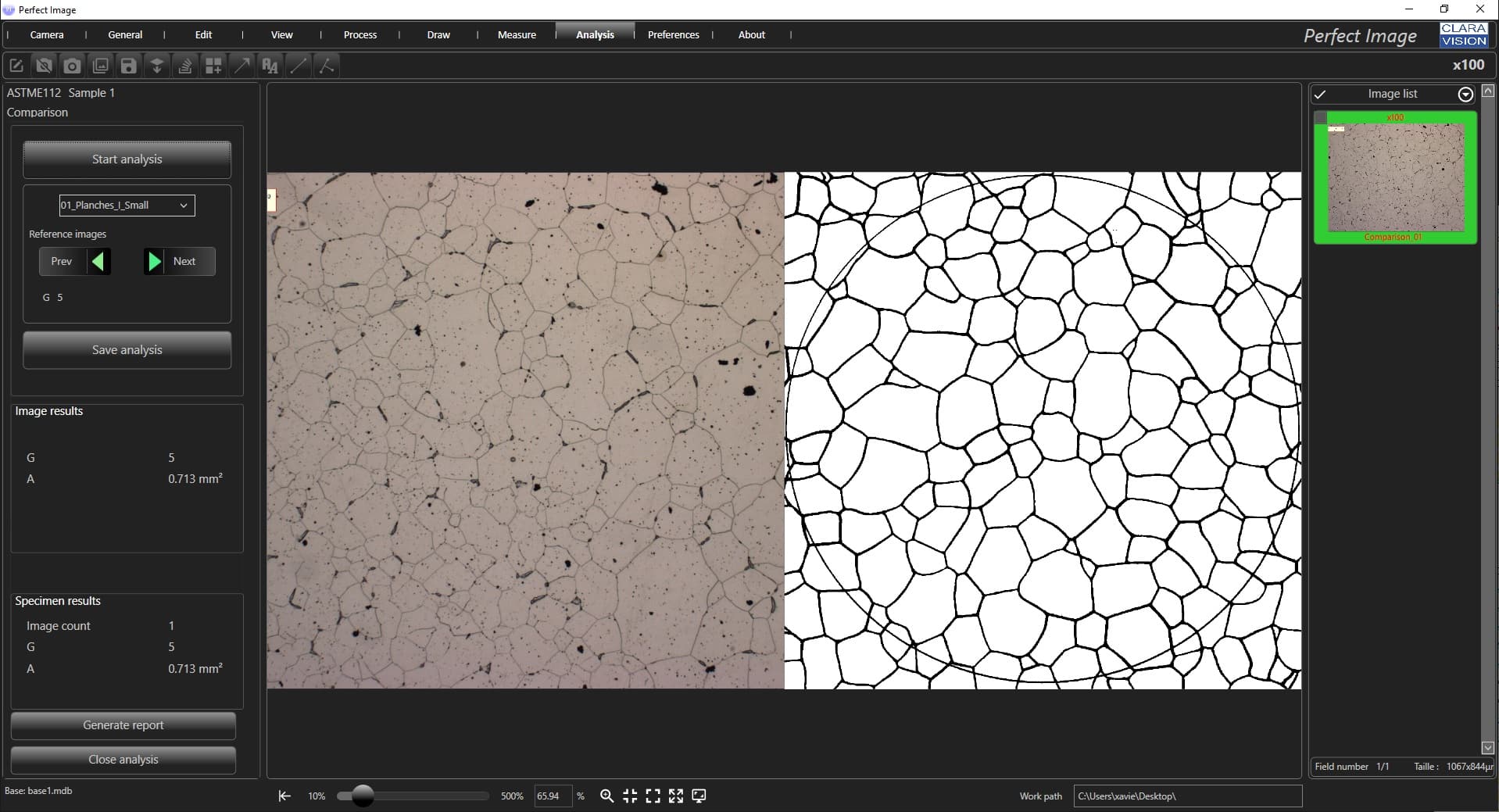

The Grani module uses several types of measurement, making it possible to calculate a sample’s “G” index precisely. Using ASTM E112 and NF ISO 643 standards, the software will conduct a comprehensive set of measurements, providing you with a detailed report. You will then be able to analyse with precision the size of the grains that are present in your sample.

The three different measurement types are:

- Image comparison

- Intercepts

- Planimetry

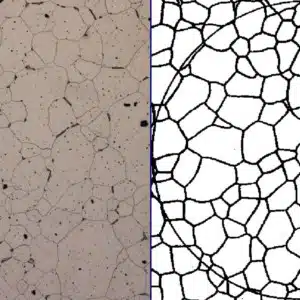

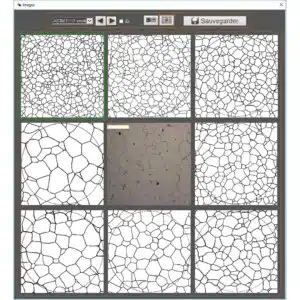

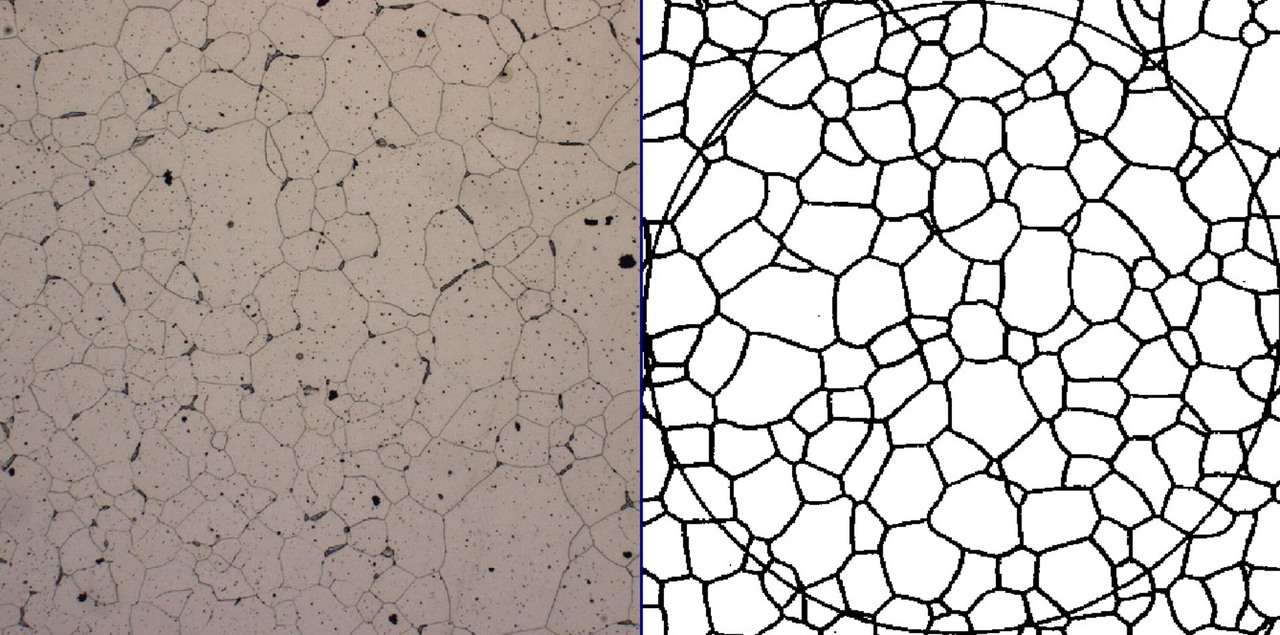

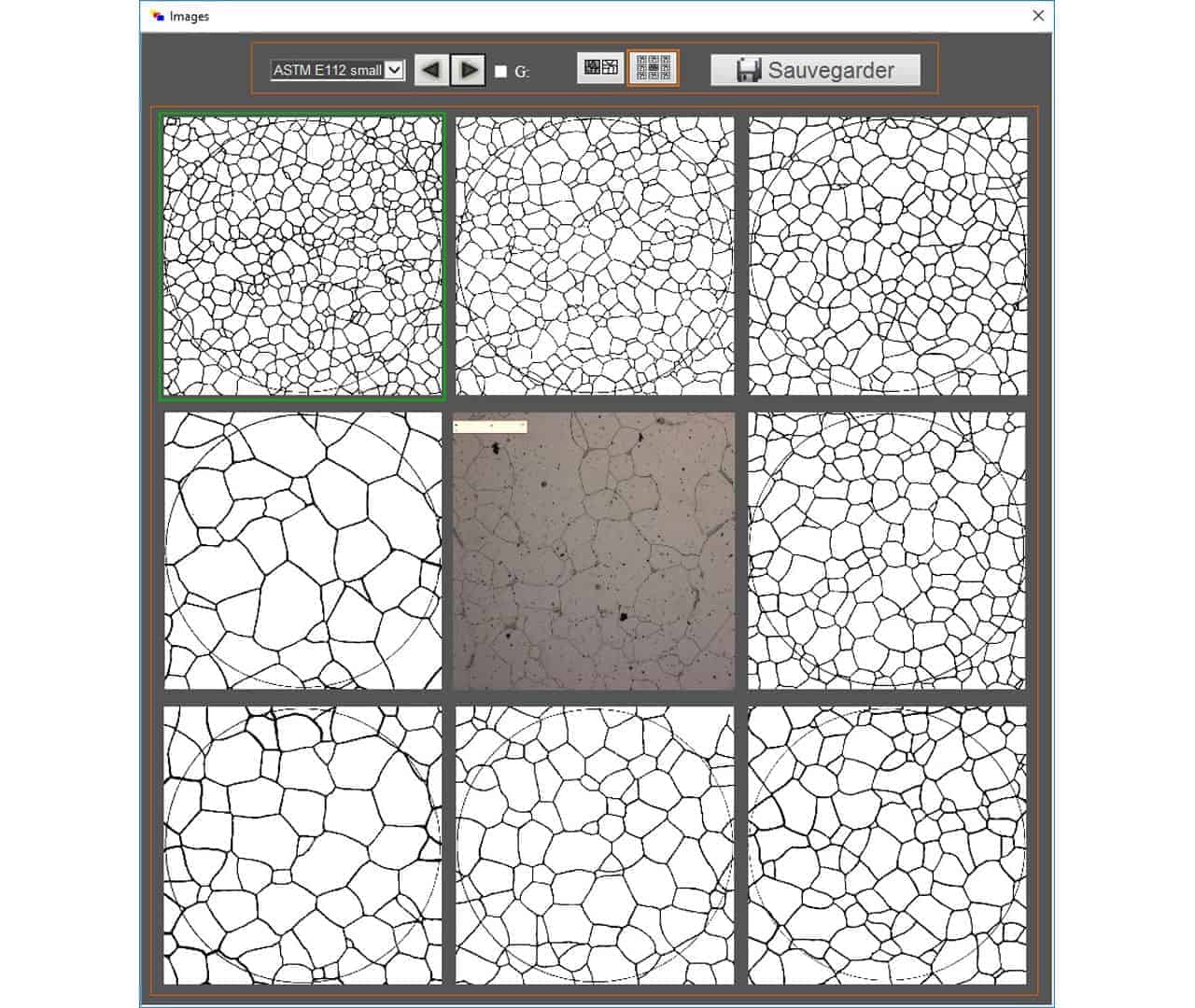

Image comparison will enable the operator to quickly estimate the size of the grains in the image. A split screen displays the captured image and reference images simultaneously.

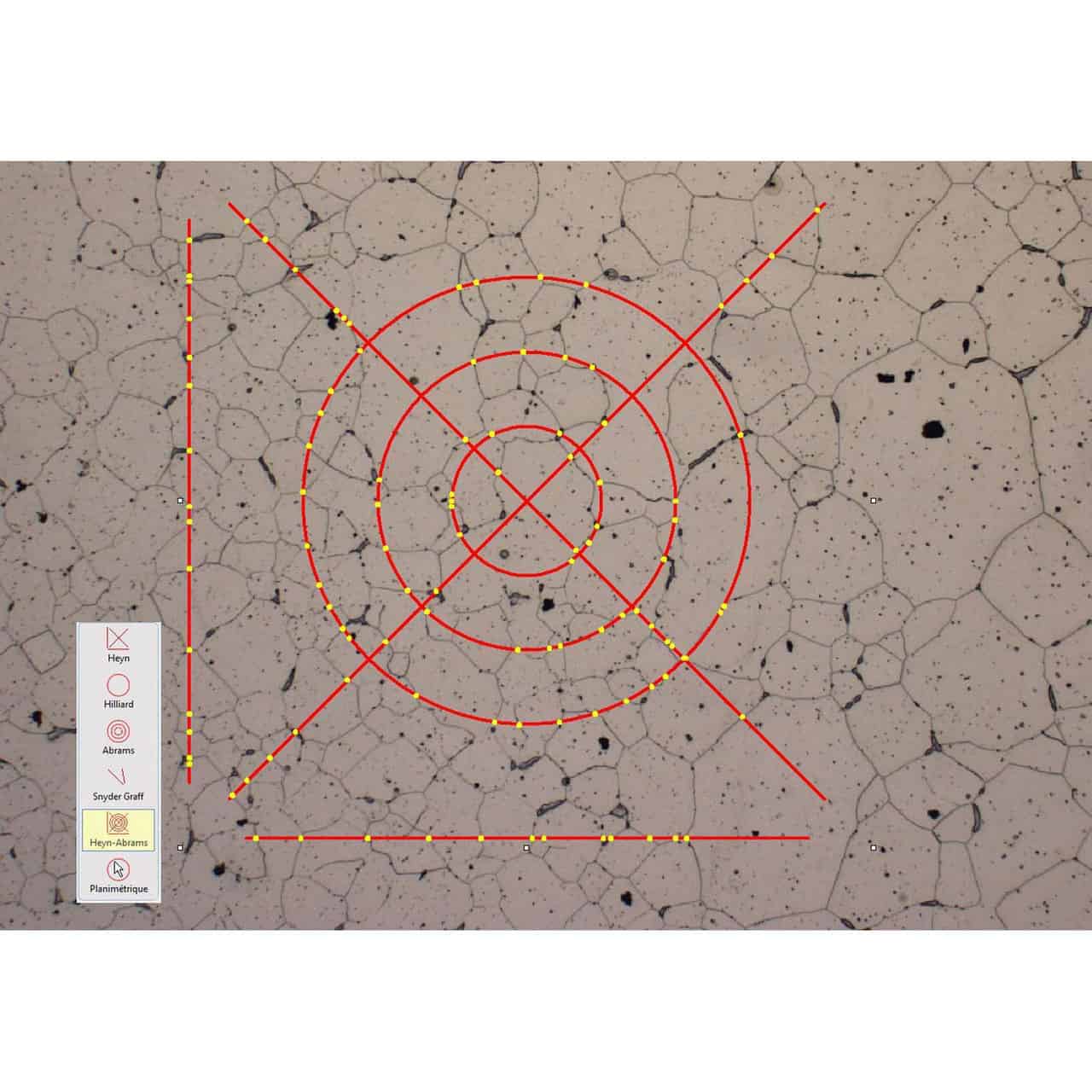

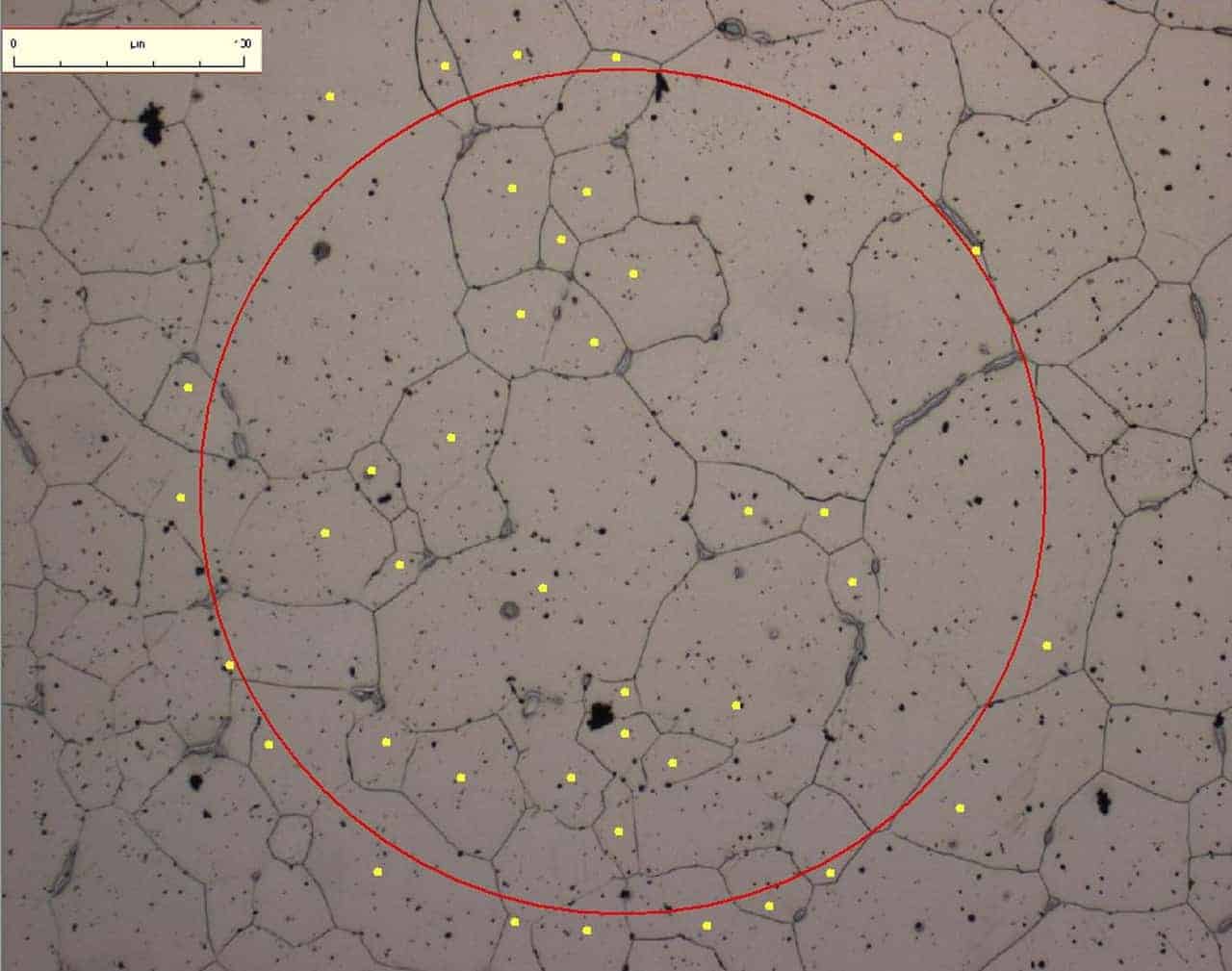

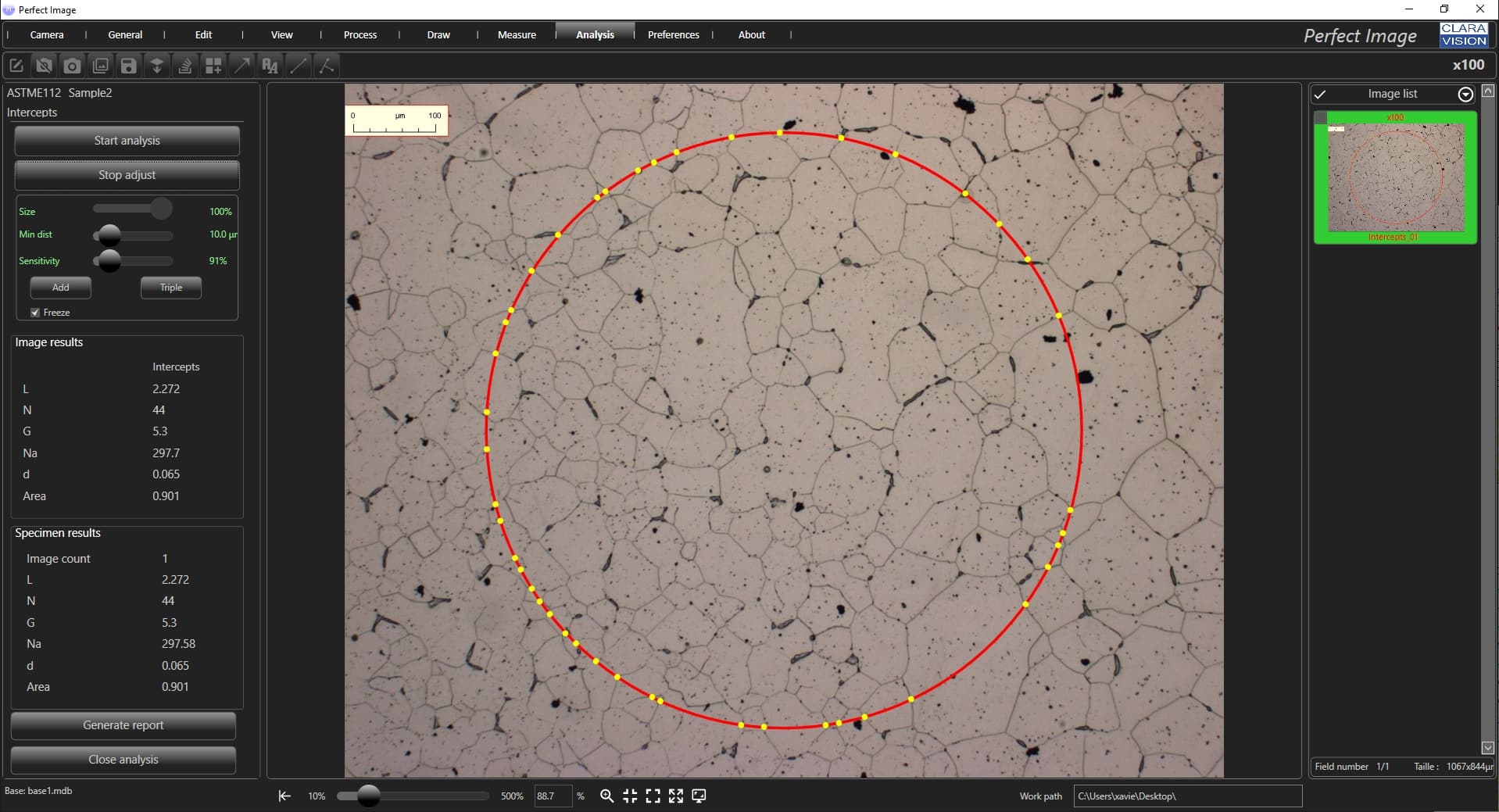

Intercept measurement is a little more comprehensive and repeatable. Using the 5 mask overlays provided (Heyn, Abrams, Hilliard, Heyn/Abrams, Lines…), you can perform a more precise measurement for calculating the size of the grains in your sample. By detecting the grain boundaries, the different mask overlays will help you calculate the “G” index efficiently. You will also be able to adjust their position manually on the grain boundaries if there are artifacts on your image. This method reduces calculation errors and can be supplemented by the planimetry measurement method.

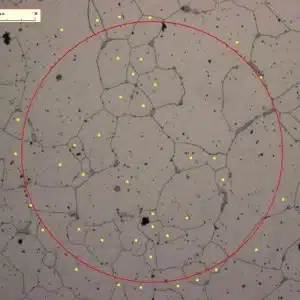

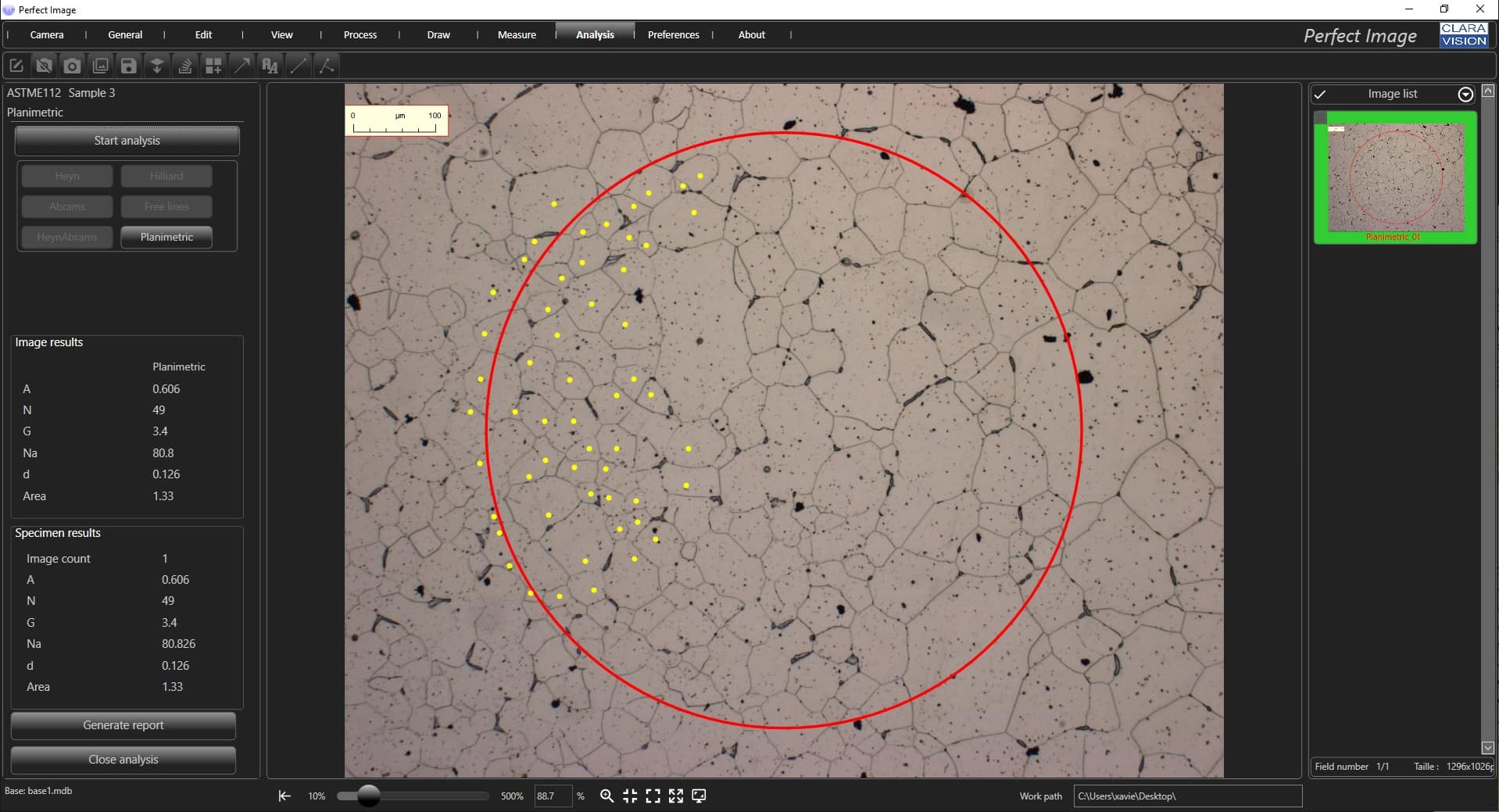

The planimetry measurement method can also be applied, and is in fact indispensable for complex samples. Using this method, the grains are counted individually for reliable, repeatable and exhaustive measurement. The operator only needs to save the data to compare the results with the other grain size calculation methods.

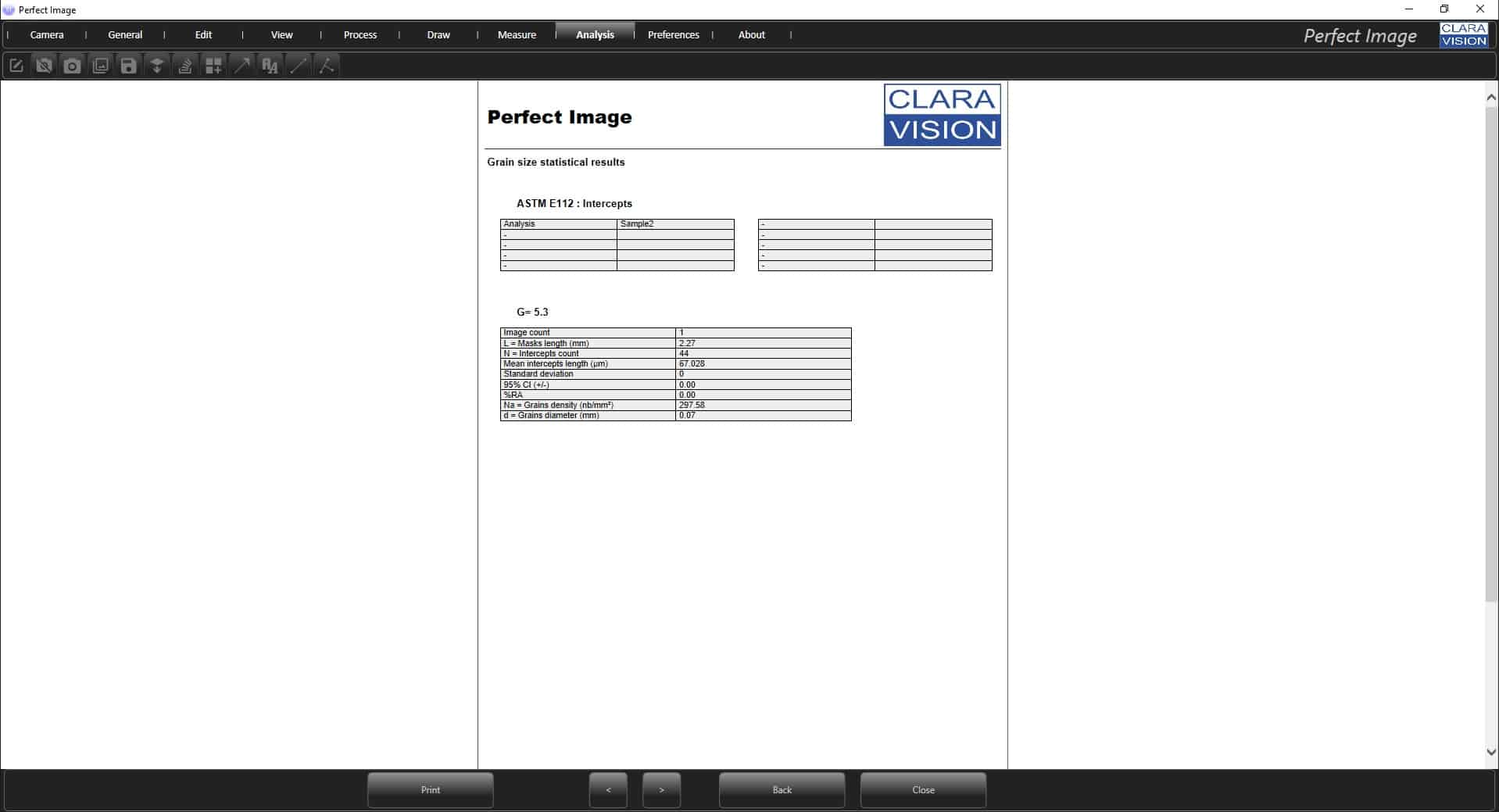

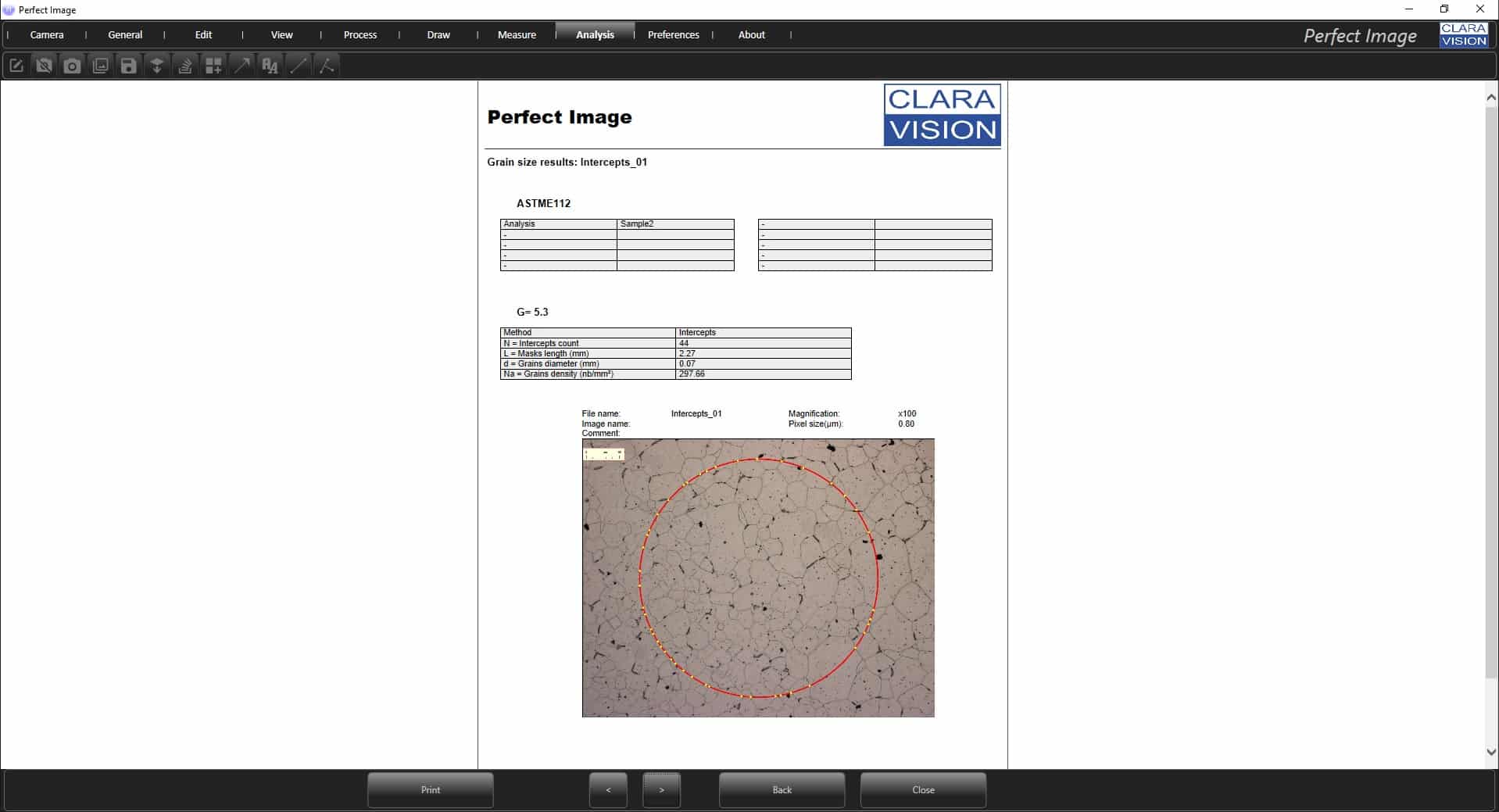

Automated measurement reports

Whichever method is used to calculate grain size, all of the results are stored automatically. Previous studies can be viewed, amended or supplemented at any time.

Study reports are created automatically at the click of a button, and include the statistical data on grain size measurement in your metallography sample, as well as the results for each image in your study.